Rolling vehicles

- Trains

- High speed

- Locomotives

- Metro

- Trams

We design and produce structures in light alloy, stainless steel and steel for locomotives, railway carriages, underground railways and trams. The design, industrialization and production of these products is performed by strictly following the reference standards for the industry.

In the field of product design, CMC Group prepares each project according to the customers' needs in order to optimize costs and improve product quality.

The first projects were carried out in the late 80s specifically on structures such as converter frames for high-speed Italian trains (Pendolino).

Afterwards, this methodology was applied to many other jobs, not only for the Italian market, but also for European markets, for projects such as roof structures for locomotives and parts for high speed trains.

In addition to welding technology, we introduced rivetting for railway vehicle structures such as roofs, traction and converter structures, air conditioning system structures and battery charger cases.

The introduction of these new technologies resulted in considerable technical and economic advantages: greater precision, no deformations and improvement in structural integrity.

This is especially true for aluminium alloy structures and for structural verification in extreme conditions, such as at a temperature of -40° C for example.

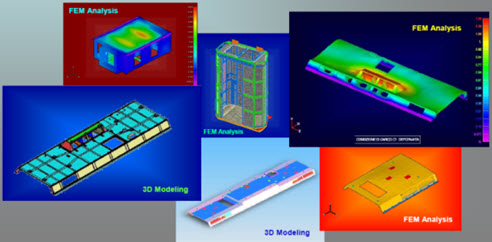

The use of the FEM (Finite Element Method) for calculations has allowed us to obtain innovative and much appreciated results regarding cost containment and improvement in product quality.